Model:SP131

Color:brown

Specifications:20kg/bucket,200kg/bucket,1100kg/ton bucket.

Performance:

1. No solvent, curing in water.

2. Low dosage, high strength.

3. High expansion, good filling.

4. Easy to use and can be pumped.

∎Product Description

SP131 polyurethane is a wet curing one component polyurethane adhesive.During the curing process,it will foam and expand,which can flatten the uneven surface.

∎Typical Applications

It is applicable to the bonding of sandwich panels and skin materials.SP131 has good adhesion to wood,plastic,metal,glass fiber,mineral wool,etc.

∎Key features

1.Solvent free;

2.Low dosage,high strength;

3.High expansion and good filling;

4.It is easy to use and can be pumped.

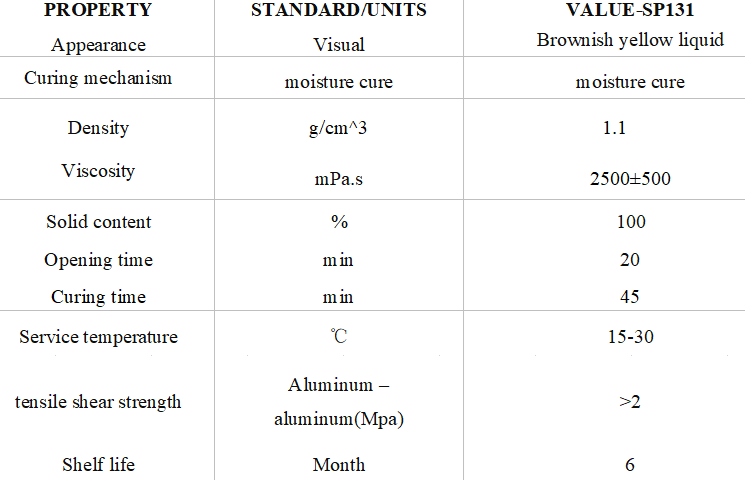

∎Technical Data Table

∎Directions for Use

Before use,

please be sure to read the material safety data sheet to understand the corresponding preventive measures and safety suggestions.In addition,for chemical products that are exempt from mandatory labeling,relevant precautions should always be observed.Please also refer to the local safety instructions and contact SEPNA for analytical support.

This product is only suitable for experienced professional users.Before use,the actual substrate and conditions must be tested to ensure adhesion and material compatibility.

Substrate pretreatment

The surface must be clean,dry and free of grease,oil,dust and pollutants.After cleaning,physical or chemical pretreatment may be required,depending on the surface and type of material.The type of pretreatment must be determined by testing.

Construction

Generally,the amount of glue applied is between 100-300 g/m2 according to the type of substrate to be bonded.For a specific base material combination,the amount of glue must be determined by test.

SP131 is very suitable for automatic applications.For manual application,after applying with a trowel,spray 10%water mist on the surface,and stick the parts together before the end of the opening time.

In order to make the substrate and the adhesive have a void free contact,sufficient bonding pressure is required.The specific pressure depends on the core material and must be determined by test.The pressure must always be lower than the maximum compressive strength of the core material.Once the stamping is started,do not release the pressure until the stamping time is sufficient.

Curing

The mixture can be cured between 15℃-30℃.The higher the temperature is,the faster the curing speed is.The lower the temperature is,the slower the curing speed is.

During the curing process,carbon dioxide is released from the adhesive.If no substrate is porous,measures need to be taken to allow carbon dioxide to escape(for example,cavities in the bonding surface).

Cleaning

Cleaning agent can be used to remove wet glue,uncured materials(cleaning tools,equipment,substrate pollution,etc.),and the adhesive can only be removed mechanically after curing.

∎Packing and Storage

Package specification:

20kg/bucket,200kg/bucket,1100kg/ton bucket.

The products are tightly packed in iron drums,and the color and weight are marked on the certificate of conformity.

Storage:

Recommended storage temperature:15℃-30℃

Storage period(unopened original packaging):6 months

Transportation:moisture proof,rain proof,sun proof,high temperature proof,keep away from heat source,handle with care,and do not squeeze or collide.

∎Attention

Fast and keep away from children;Avoid contact with eyes and skin before curing.In case of accidental contact with skin,first scrub with soapy water or alcohol,and then rinse with clean water.In case of contact with eyes,rinse with plenty of water first,and seek medical advice immediately if necessary.

∎Safety Operation Data

MSDS isn't included here.Please read TDS,MSDS and label carefully before operation.You can get MSDS from SEPNA or other distributors,or mail to service center sepna sepna.cc,or call+86-400-882-1323.

∎Warranty and Liability

All product properties and application details based on information believe to be reliable and accurate.But you still need to test its property and safety before application.The advices we supply don't apply in any circumstances.SEPNA don't make assurance of any other applications outside the specification until SEPNA supply a special written guarantee.SEPNA is only responsible to replace or refund if this product is defective within the warranty period stated above.SEPNA makes it clear that will not be liable of any accidents.